Manufacturing & FactoryOffice Chair ManufacturerBulk OrderOEM Office ChairOffice Chair Factory

2026年1月9日

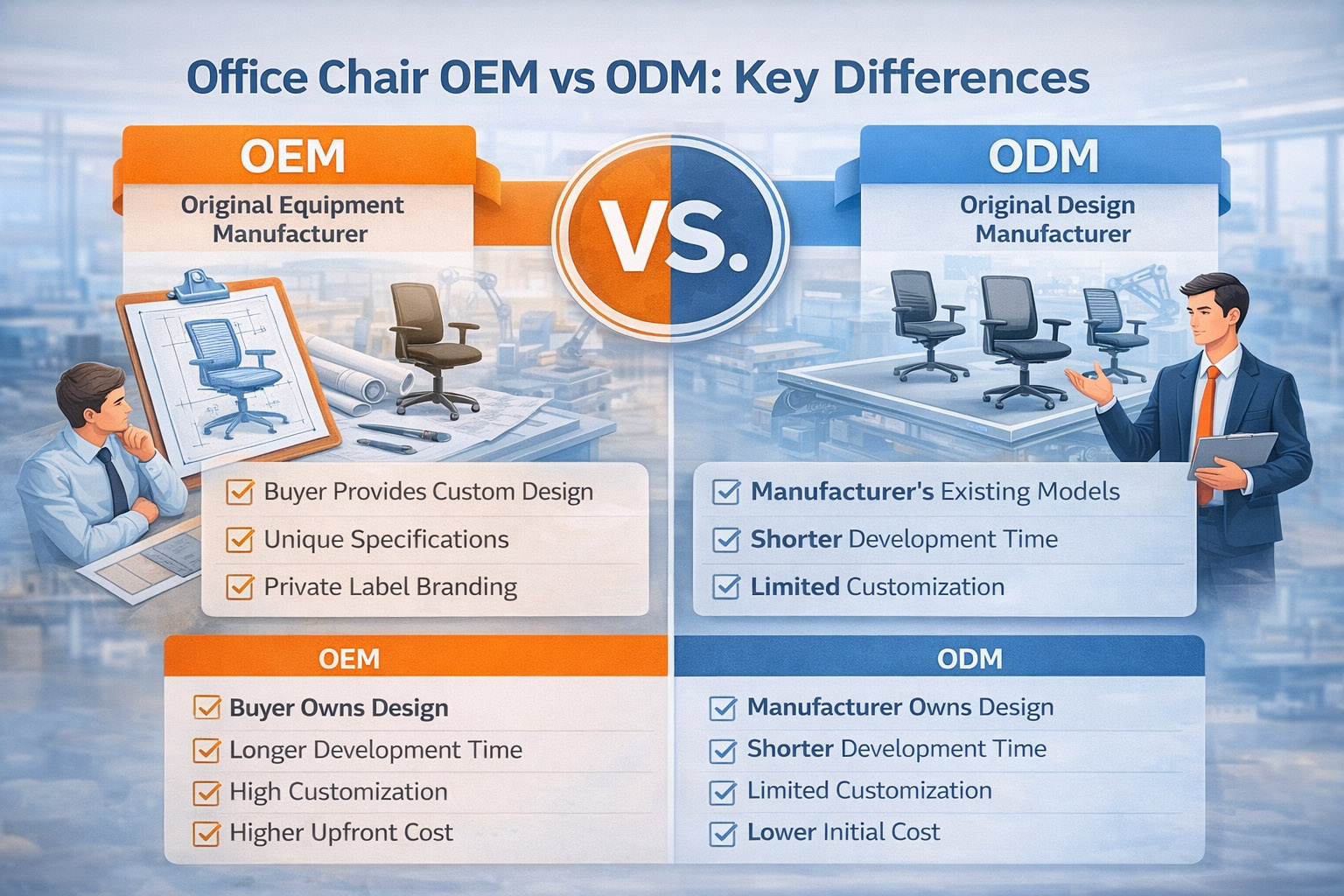

Office Chair OEM vs ODM: What Buyers Should Know Before Ordering

Understanding the difference between OEM and ODM office chairs helps buyers choose the right sourcing model for customization, branding, and production efficiency.

Office Chair OEM vs ODM: Understanding the Difference

When sourcing office chairs from overseas manufacturers, buyers often encounter two common business models: OEM and ODM.

Although both are widely used in the furniture industry, they serve different sourcing goals, especially when it comes to customization, branding, and product development.

This article explains the key differences between OEM and ODM in office chair manufacturing to help buyers select the most suitable model for their projects.

What Is OEM in Office Chair Manufacturing?

OEM (Original Equipment Manufacturer) refers to a model in which the buyer provides the product design, specifications, or brand identity, and the manufacturer produces office chairs based on those requirements.

In OEM projects, buyers usually control:

- Product design or reference models

- Technical specifications

- Branding, logos, and packaging

The manufacturer focuses on production, assembly, and quality control according to the buyer’s instructions.

What Is ODM in Office Chair Manufacturing?

ODM (Original Design Manufacturer) means the manufacturer provides existing product designs that buyers can select and brand.

In ODM projects, the manufacturer typically offers:

- Pre-developed chair models

- Tested structures and mechanisms

- Design support for minor modifications

Buyers mainly customize branding, colors, materials, or packaging while using the manufacturer’s existing designs.

Key Differences Between OEM and ODM

Product Design Ownership

- OEM: The buyer owns or controls the design.

- ODM: The manufacturer owns the original design.

Development Time

- OEM: Longer development cycle due to new design and testing.

- ODM: Faster time to market using existing models.

Customization Level

- OEM: High flexibility in structure, materials, and appearance.

- ODM: Limited to modifications within existing designs.

Cost Structure

- OEM: Higher upfront cost for development and tooling.

- ODM: Lower initial cost, as designs and tooling already exist.

Risk Level

- OEM: Higher risk but more differentiation.

- ODM: Lower risk with proven product structures.

When OEM Is the Better Choice

OEM is often suitable when:

- Unique product design is required

- Strong brand differentiation is needed

- Long-term volume justifies development cost

When ODM Is the Better Choice

ODM is often suitable when:

- Faster market entry is needed

- Budget or volume is limited

- Buyers prefer tested and proven designs

How Buyers Can Choose the Right Model

Buyers should consider:

- Product differentiation goals

- Order volume and long-term plans

- Budget for development

- Time-to-market requirements

Both OEM and ODM models have their advantages depending on business strategy.

FAQ

Q1: Can OEM and ODM be combined?

Yes. Many projects start with ODM and later move to OEM as volumes increase.

Q2: Is ODM less professional than OEM?

No. ODM uses proven designs and can offer high quality and stability.

Q3: Which model is better for new brands?

ODM is often more suitable for new brands due to lower cost and faster launch.